Tel: 0536-3399235

Tel: 0536-3399235

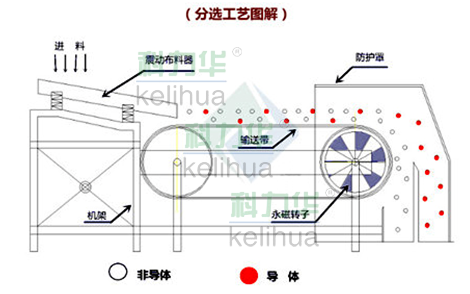

Equipment working principle:

1.When the intelligent metal sorting machine is working, the metal in the material is detected by the metal detector, and the metal detector outputs a signal to the central processing unit. The central processing unit analyzes the position, size, and arrival time of the metal at the gas knife based on the signal from the metal detector. The metal is blown out of the material through a high-pressure gas body, and non-metallic materials fall down with the conveyor belt to complete the metal sorting.

2.Material selection: Choose from all metals such as iron, stainless steel, copper, aluminum, lead, zinc, etc., and can adapt to most materials such as granular and irregular shapes.

3.Metal detector: Adopting German imported detectors, it has a large detection depth, high detection accuracy, and strong ability to identify metals.

4.Air knife: can process air knives according to different materials, with strong adaptability.

5.Material distribution device: The material distribution device can be adjusted in front, back, and rotation, making it easy to adjust and highly adaptable.

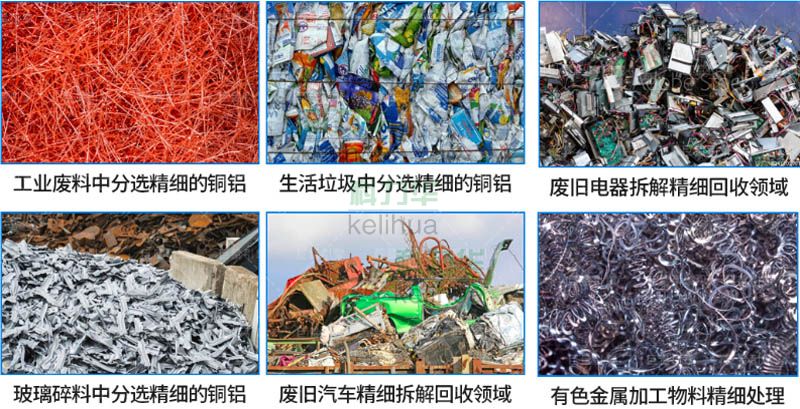

Application Area :

Advantages and Characteristics:

1.The eccentric magnetic roller used can prevent magnetic substances from entering the surface of the magnetic roller, protecting the magnetic roller and operating belt.

2.The magnetic roller adopts magnetic protection to prevent the magnetic system from falling off during high-speed operation.

3.The bearings are imported, with a long service life and good operation.

4.For lighter and smaller surface area materials, the sorting effect is better than that of concentric materials.

5.Adopting an intelligent touch control cabinet system and variable frequency control, the operation is smoother and more reliable.

6.Adopting PLC programmable control, one click start, simple operation.

7.The whole machine adopts special technology and is built with minimal noise and vibration during equipment operation.

8.The entire machine is equipped with various detection and alarm devices to monitor the real-time operation of each key component.

How to choose a vortex current gold sorting machine?

一、When customers choose eddy current sorting machines, they should first determine the following points

1、Material handling capacity, material handling capacity per day and material handling capacity per hour

2、Material diameter: minimum material diameter and maximum material diameter

3、Material composition, such as scrap broken materials containing copper, aluminum, stainless steel, rubber, etc

4、What is the proportion of non-ferrous metals in the material, such as the copper and aluminum content of scrap crushing material is generally 5%-10%

二、The material details and processing capacity are provided to the eddy current sorting machine manufacturers, you can mail a small amount of 5-10 kilograms of material to the sorting machine manufacturers, the current sorting machine manufacturers after the test to determine the sorting rate, processing capacity, equipment model, the required process flow, etc., equipment purchase must be combined with their own material details to purchase, equipment model is mainly based on the material processing capacity and sorting accuracy.

Product Shooting:

Live Shooting:

| Professional manufacturer of renewable resource equipment

| Professional manufacturer of renewable resource equipment

WeChat

WeChat

鲁公网安备37072402370767号

鲁公网安备37072402370767号