Tel: 0536-3399235

Tel: 0536-3399235

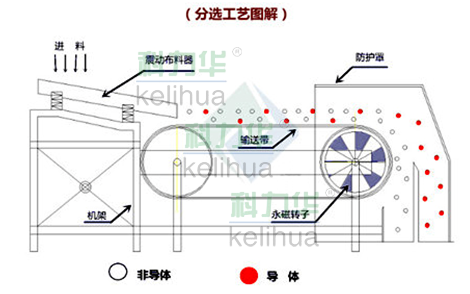

Equipment working principle:

The eccentric eddy current metal sorter is designed based on the principle that a conductor generates an induced current in a high-frequency alternating magnetic field. When working, the high frequency alternating magnetic field is generated on the surface of the sorting magnetic roll. When the conductive non-ferrous metal passes through the magnetic field, the eddy current will be induced in the non-ferrous metal. The eddy current itself will produce a magnetic field in the opposite direction of the original magnetic field. It can be separated from other non-conductors or non-metallic substances to achieve the purpose of sorting.

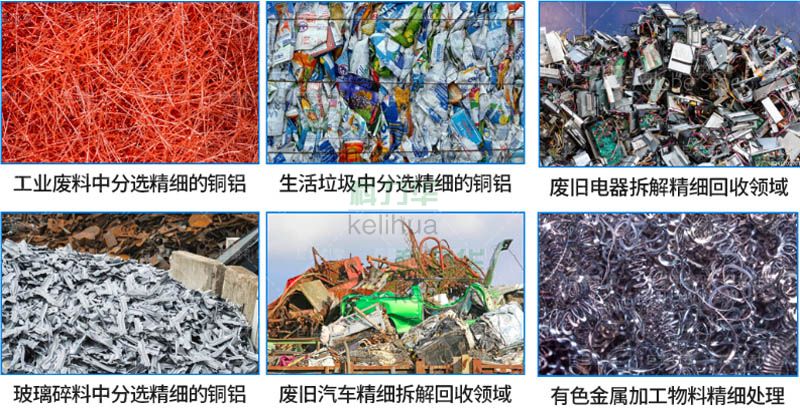

Application Area :

Advantages and Characteristics:

1.The eccentric magnetic roller used can prevent magnetic substances from entering the surface of the magnetic roller, protecting the magnetic roller and operating belt.

2.The magnetic roller adopts magnetic protection to prevent the magnetic system from falling off during high-speed operation.

3.The bearings are imported, with a long service life and good operation.

4.For lighter and smaller surface area materials, the sorting effect is better than that of concentric materials.

5.Adopting an intelligent touch control cabinet system and variable frequency control, the operation is smoother and more reliable.

6.Adopting PLC programmable control, one click start, simple operation.

7.The whole machine adopts special technology and is built with minimal noise and vibration during equipment operation.

8.The entire machine is equipped with various detection and alarm devices to monitor the real-time operation of each key component.

How to choose a vortex current gold sorting machine?

一、When customers choose eddy current sorting machines, they should first determine the following points

1、Material handling capacity, daily material handling capacity and hourly material handling capacity

2、Material diameter: minimum material diameter followed by * * material diameter

3、Material composition, such as scrap steel crushed material that contains copper, aluminum, stainless steel, plastic, rubber, etc.

4、The proportion of non-ferrous metals in the material, for example, the content of copper and aluminum in scrap steel crushed material is generally 5% to 10%.

二、When providing material details and processing capacity to eddy current separator manufacturers, it is possible to mail a small amount of 5-10 kg of materials for the manufacturer to test. After the testing, the separator manufacturer will determine the separation rate, processing capacity, equipment model, and required process flow. When purchasing the equipment, it is important to select based on the specific details of your materials, and the equipment model is mainly determined by the material processing capacity and separation accuracy.

Product photos (actual product photography):

Actual photos taken on the spot:

| Professional manufacturer of renewable resource equipment

| Professional manufacturer of renewable resource equipment

WeChat

WeChat

鲁公网安备37072402370767号

鲁公网安备37072402370767号